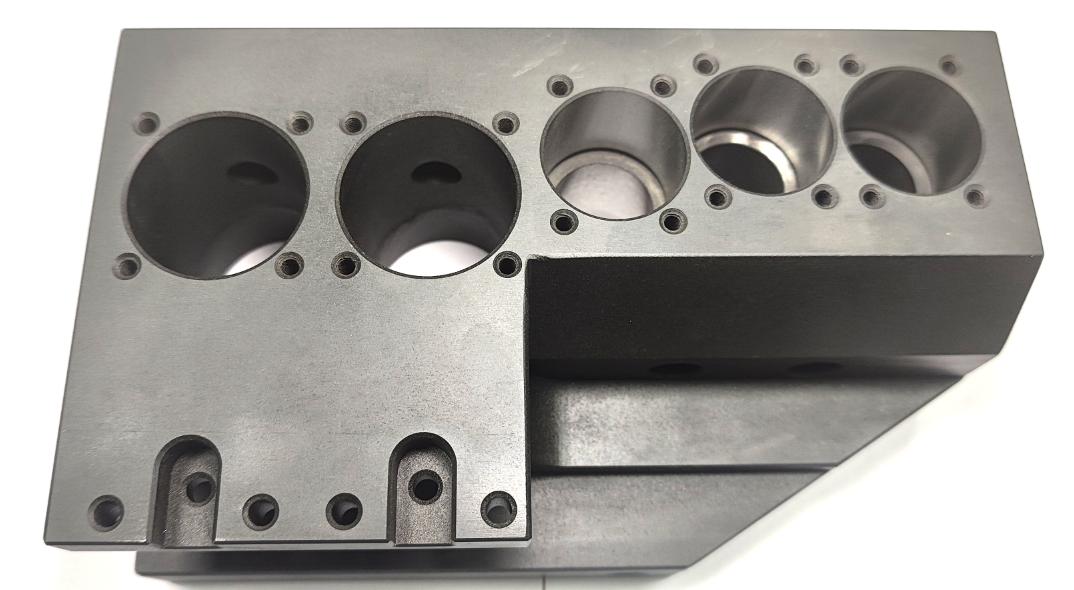

Our high-speed machining centers are equipped to offer automated precision machining services with fast quotes and short lead times. As a full-service CNC machine center, 1F confidently accommodates the needs of our clients whether quoting an existing design or designing something from scratch. 1F extensive machining capabilities, years of experience, and state-of-the-art technology, allows your project to be completed quickly and efficiently to the tightest of tolerances.We are experienced in working with a variety of metal and plastic materials including aluminum, Mild steel, Alloy steel, Brass, Copper, Bronze, Stainless steel, and titanium.

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

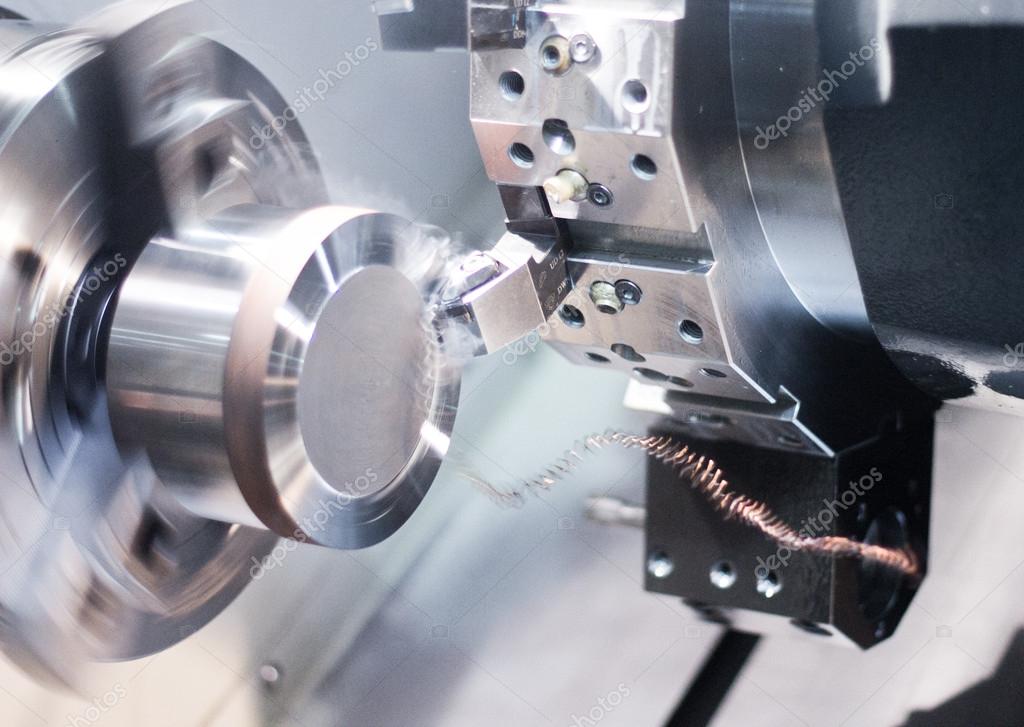

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

CNC Machining Material we work with:

| CNC Metal Machining Material: | CNC Plastic Maching Material | CNC Special Material Machining |

| Tungsten | ABS | Ceramic |

| Brass | Nylon | Tungsten Steel |

| Copper | POM | |

| Aluminum | PTFE | |

| Tianium | PMMA | |

| Stainess Steel | Polycarbonate | |

| Bronze | Polysyrene | |

| Polyethylene |

Processing standard

Processing standard:

1. For size (length, width, height, diameter) and position (location, concentricity, symmetry) features, a tolerance of ± 0.005" (metal) or ± 0.010" (plastic and composite materials) shall follow ISO 2768 unless otherwise specified.

2. Machined surfaces shall have a surface finish of 125 Ra or better. Machine marks may leave a swirling pattern.

By default, sharp edges will be chamfered and deburred. Sharp edges must be specified and indicated on the drawing if they need to be retained.

3. Transparent or translucent plastics will have a matte finish and may leave a swirling pattern. Sandblasting will create a frosted surface on transparent plastics.

4. Tolerances for soft rubber or similar compressible materials may not be guaranteed by 1F.

5. General tolerance guidelines for orientation and form features are outlined below, unless different tolerances are agreed upon in your quotation. These features include parallelism, perpendicularity, cylindricity, flatness, roundness, and straightness.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat