Al2O3 Alumina Ceramic

3.75 – 3.94 g/cm3

99.7% Al2O3 (Alumina /Aluminium oxide)

C799

78 × 10-7 / °C (20–700 °C)

86 × 10-7 / °C (20–1000 °C)

Max. operating temperature under

mechanical load: approx. 1700 °C

Good thermal shock resistance

Specific heat capacity: 990 J kg-1 K-1

(20–100 °C)

Modulus of elasticity: 300–380 GPa

Mohs hardness: 9

Modulus of rupture: 300 GPa (20°, 3-Point)

Electric strength: 17 kV/mm (IEC 672-2)

Specific DC-resistance: 1014 Ω cm (20°C)

Water absorption capacity: ≤ 0.2%

Leak rate: 10-10 hPa dm3 s-1 (20 °C)

High purity of 99.7%

High mechanical strength and wear resistance

Excellent thermal resistance

Outstanding insulation characteristics

Extreme dielectric strength

Exceptional tribological properties

Can be processed with conventional abrasive tools

Low dissipation factor

High chemical resistance

Good metallizability

Very hard material structure

Heat-resistant ceramic components

Electrical performance insulators

Space applications

Dielectric for capacitors

Welding nozzles

Ceramic Bushings

Wear-resistant components

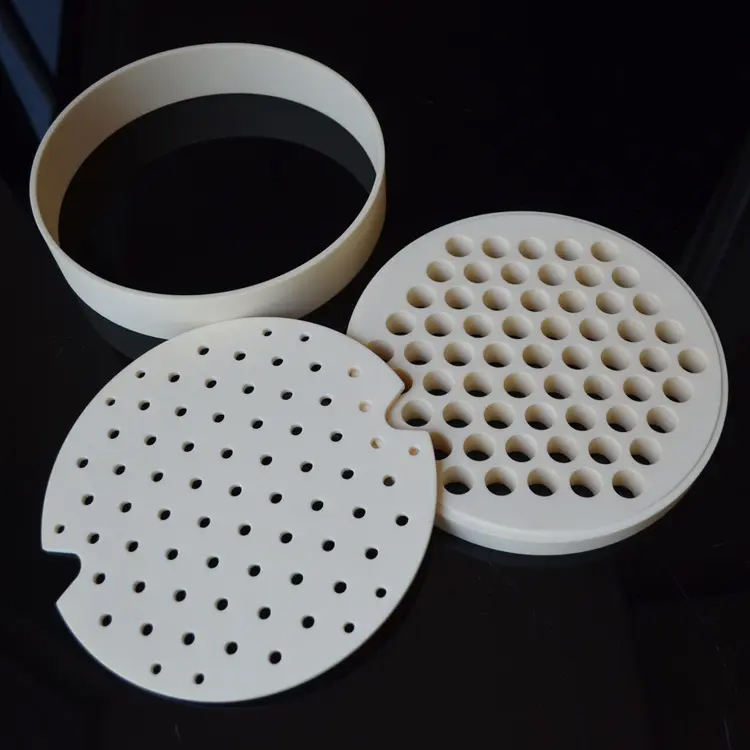

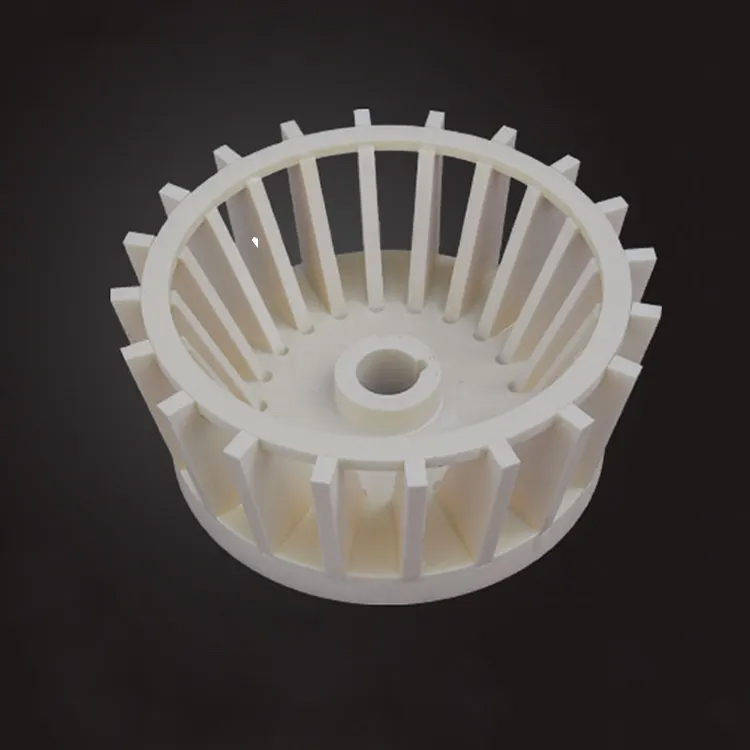

Al2O3 alumina is a white and opaque high-performance ceramic with exceptional physical characteristics. It is very temperature resistant and offers excellent mechanical strength. The material, also called aluminum oxide, offers outstanding electrical insulation properties, low dissipation, and tremendous dielectric strength. These properties enable high voltage electrical applications.

The mechanical characteristics of advanced Al2O3 ceramic materials are also remarkable. Hence, aluminum oxide materials are ideal for producing components that need to withstand high mechanical load as Al2O3 offers an exceptional wear resistance. So, due to its superior tribological, much longer lifetimes of parts and workpieces are achieved with Al2O3. Furthermore, the chemical strength of alumina is considerable. It can resist most acids and alkalis, even at increased temperatures.

Since grinding aluminum oxide materials using conventional abrasive tools on conventional CNC machines is possible, the unique ceramic material allows the manufacturing of complex workpieces. The potential complexity of the components manufactured from aluminum oxide is limited only by the machinery used, so even complex precision workpieces are produced from Al2O3 aluminum oxide.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat