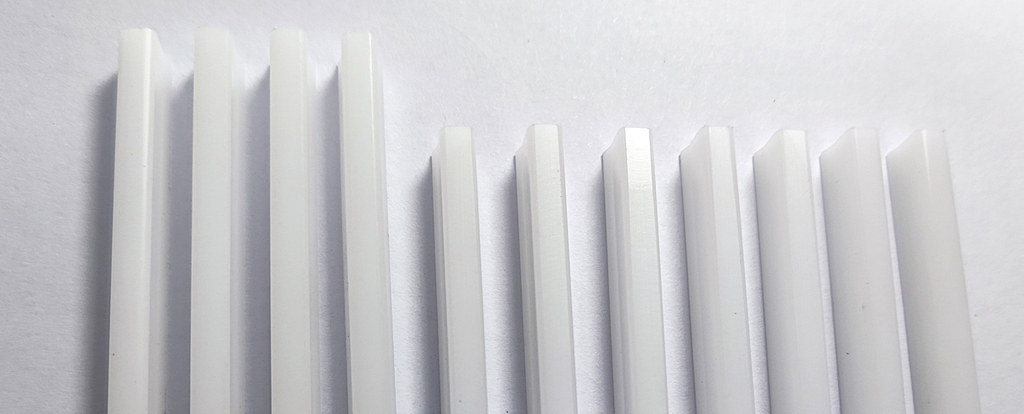

Nylon Positioning fixture

Material: Nylon

Finishing: No

Tolerance: ±0.001mm

Customized: Yes

Application: Electronic Product

MOQ: 1pc

Item | Nylon Positioning fixture | Material | Nylon |

Nylon Positioning fixture Tolerance | ±0.001mm | CNC Machining Type | CNC Milling |

MOQ | 1pc | Standard | Nonstadnard parts |

Application | Electronic Product | Finishing | No |

Sample | Available | Customzied | Yes |

Drawing Format | PDF/DWG/IGS/STP/ etc. | Surface Roughness | Min Ra 0.1~3.2 |

MOQ | 1pc | Sample | Available |

Quality Assurance | ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV | Business type | Manufacturer |

A nylon positioning fixture is a type of jig or fixture that is used to accurately position and hold workpieces in place during machining or assembly operations. It is made of nylon, a durable and lightweight plastic that is resistant to wear and corrosion.

Nylon positioning fixtures are available in a variety of shapes and sizes to accommodate a wide range of workpieces.

Nylon positioning fixtures are often used in the following applications:

Woodworking: Nylon positioning fixtures are used to accurately position and hold wood pieces in place while they are being drilled, cut, or routed.

Metalworking: Nylon positioning fixtures are used to accurately position and hold metal parts in place while they are being welded, machined, or assembled.

Electronics manufacturing: Nylon positioning fixtures are used to accurately position and hold electronic components in place while they are being assembled or tested.

Nylon positioning fixtures have advantages over traditional metal fixtures:

Lighter weight: Nylon fixtures are significantly lighter than metal fixtures, which makes them easier to handle and position.

Corrosion resistance: Nylon is resistant to corrosion, so it can be used in wet or humid environments without rusting.

Non-marring: Nylon is a soft material that will not mar or scratch delicate workpieces.

Durability: Nylon is a durable material that can withstand repeated use.

WHY CHOOSE US?

Processing Material: We accept to processing wide range of material metal and plastic parts, Materials Avaiable Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, etc.

Surface Treatment: Different surface finishing can be made by us: polishing, general/hard/color oxidation, surface chamfering, tempering, etc.

Processing Service: CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc., can be prcessed in our workshop.

Quality Control Lab: CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement are equipped in our testing lab.

Drawing Formats: PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF are accepted by us to offer the quotation.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat