what is electroplating

what is electroplating

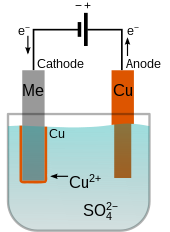

Electroplating is a process used to coat an object's surface with a layer of metal through anelectrochemical reaction.

This technique involves placing the object to be plated (known as the substrate) in an electrolyte solution containing

ions of the metal that will form the coating. An electrical current is then passed through the electrolyte, causing the

metal ions to migrate and deposit onto the surface of the object, creating a thin, even layer of the desired metal.

Chrome Plating:

Chromium is a bright white metal with a slight bluish tint. The process of depositing a layer of chromium on metals or certain non-metals through electrolysis or

chemical methodsis known as chrome plating.

Advantages: The surface resulting from chrome plating is bright white. Chrome plating can significantly improve the drawbacks of low hardness and wear resistance

in stainless steel. It exhibits minimal deformation during low-temperature processing, is resistant to oxidation, and is environmentally safe. Additionally, chrome platingdoes

not affect corrosion resistance.

Disadvantages: Rust resistance is not as strong as that of Zinc Plating.

Applications: Chrome plating is used on bright decorative components in appliances, electronics, and other products. It is applied to tools, faucets, and more.

Zinc Plating

Zinc Plating refers to the surface treatment technique of applying a layer of zinc on the surface of metal, alloy, or other materials for the purposes of aesthetics, rust prevention, and

more. The surface appears silver-white and serves purposes such as aesthetics and rust prevention.

Advantages: Low cost

Disadvantages: Moderate corrosion resistance.

Applications: It is commonly used for products like screws, circuit breakers, industrial supplies, and more.

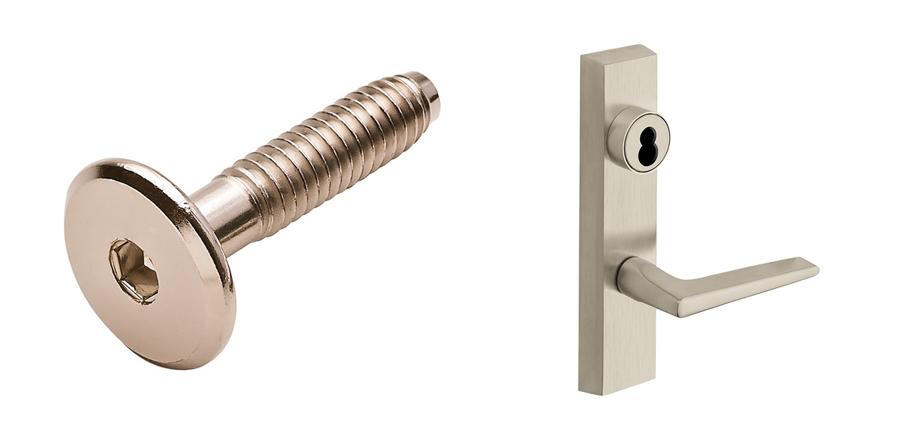

Nickel Plating

The process of depositing a layer of nickel on metals or certain non-metals through electrolysis or chemical methods is known as nickel plating. The surface resulting from nickel

plating has a slight yellowish hue.

Advantages: Primarily offers wear resistance, corrosion prevention, and rust resistance.

Disadvantages: High cost and slightly complex process.

Applications: It is commonly used for components like energy-efficient light bulb sockets, coins, hardware parts, and more.

How to use the right surface treatment technique?

It's crucial to understand the environment, stresses, chemical exposure, and other conditions the product will face. This helps determine the required attributes such as corrosion resistance,

wear resistance, aesthetics, etc.

If the goal is to prevent rust, zinc plating or chrome plating offers a better cost-effectiveness ratio. If the focus is on preventing wear, nickel plating or chrome plating are the optimal choices.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat