Ceramic Injection Molding (CIM)

Ceramic Injection Molding (CIM) is a new process for manufacturing ceramic components that combines polymer injection molding methods with ceramic preparation techniques. Similar to Metal Injection Molding (MIM) technology that emerged in the 1970s, both CIM and MIM are major branches of Powder Injection Molding (PIM) technology, developed on the foundation of mature polymer injection molding techniques. For the large-scale production of high-precision and complex-shaped ceramic products, ceramic powder molding offers significant advantages.

Advantage of ceramic parts:

- scratch resistance

- skin-friendliness

- hypoallergenic properties

- jade-like appearance

- lower cost

The up advantage of the ceramic material, make Ceramics have become the material of choice for smart wearables. Ceramic injection molding is one of the primary molding processes used for the production of ceramic exterior components in today's smart wearable devices.

Characteristics of CIM Ceramic Injection Molding Technology

Comparison of CIM with Other Molding Methods

Molding Method | Molding Material | crystal morphology | Product Size (cm) | |

| Diameter | Thickness | |||

| Injection Molding | Powder+Organic Material (10~25%) | Complicated | 30~0.5 | 3.0~1 |

| Machine Press | Powder+Organic Material (4~8%) | Simple | 20~1.0 | 0.8~1.0 |

| Isostatic Pressing | Powder+Organic Material (3~8%) | More complex columnar and spherical shapes | 150~3 | 150~1.9 |

| Slip Casting | Powder+ Different Material+Water | Extreme Complicated | 150~20 | 3.0~0.3 |

| Tepe-Casting | Powder+Different Material+Organic solvents | Simple | 200~15 | 0.2~0.003 |

| Extrusion | Powder+Organic Material+Water | Rods and Tubes | 30~20 | 2.5~0.01 |

Advantages & Disadvantage of Ceramic Injection Molding.

1. The molding process is highly mechanized and automated, resulting in high production efficiency, short molding cycles, and high green part strength. The process can be precisely controlled (program-controlled), making it suitable for large-scale, industrial production.

2. CIM can achieve near-net shaping of various complex geometric and specially required small ceramic components, reducing the need for costly ceramic machining or post-processing and lowering production costs.

3. Ceramic products produced through CIM exhibit extremely high dimensional accuracy and surface finish.

Disadvantages: High initial equipment investment and processing costs, making it suitable primarily for large-scale production.

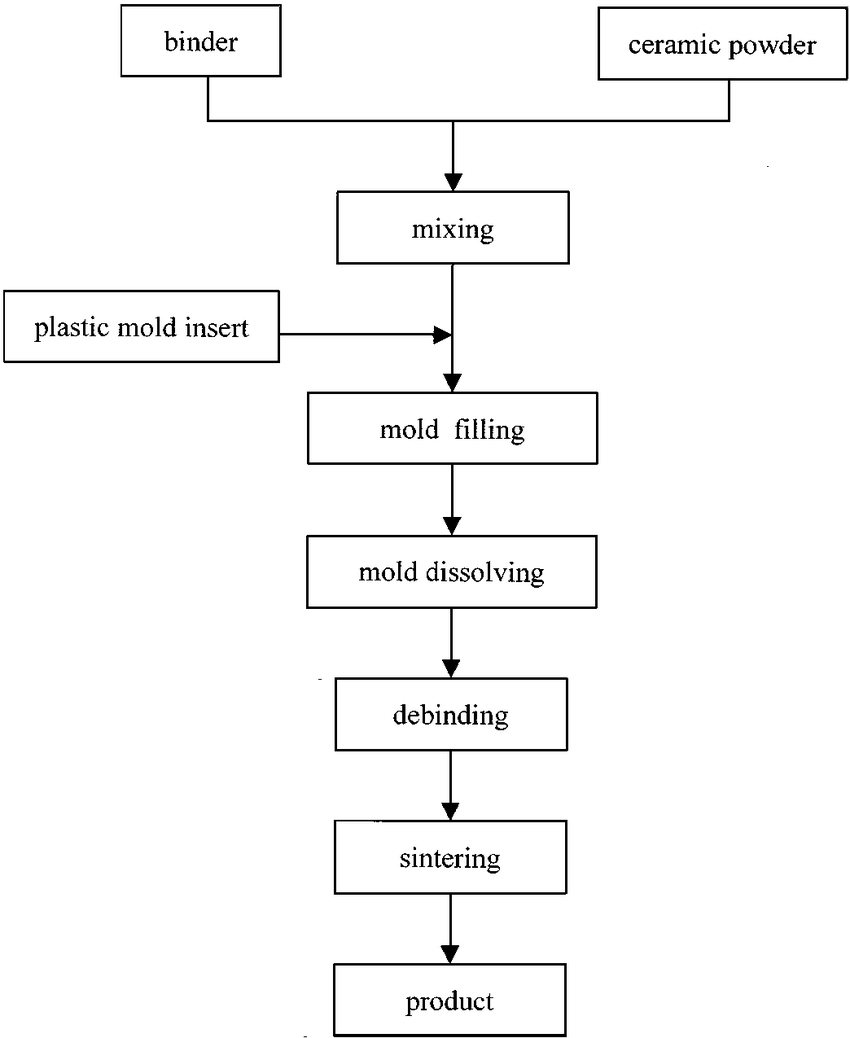

Process Flow of CIM Ceramic Injection Molding

The manufacturing process of ceramic precision injection moldingmainly includes the following four steps:

1. Feedstock Preparation:

Feedstock is a mixture of powder and binder. The injection process requires the feedstock to have good flowability, necessitating the selection of suitable powders and an appropriate binder system. Mixing them in the correct proportions and under specific temperature conditions is critical to ensure smooth subsequent processes and enable products to move from the laboratory to the high-tech market. Therefore, feedstock preparation is a crucial step in the entire process.

2. Injection Molding and Mold Design:

Improper control of the injection molding process can lead to various defects in the product, such as cracks, pores, weld lines, delamination, and separation of powder and binder. These defects may only become apparent after debinding and sintering. CIM often uses multi-cavity molds with varying cavity sizes, and wear during mold usage can result in variations in part dimensions. Additionally, the use of recycled feedstock can affect viscosity and rheology. Therefore, controlling and optimizing molding parameters such as injection temperature, mold temperature, injection pressure, and hold pressure are crucial for reducing green part weight fluctuations, preventing component segregation and separation, and improving product yield and material utilization.

The mold design for CIM technology primarily focuses on controlling the flow of feedstock in the mold cavity during injection molding. As CIM products are mostly complex in shape, require high precision, and are small in size, careful design and arrangement of the feed inlet, runner length, and venting holes are necessary. Furthermore, mold design necessitates a clear understanding of the rheological properties of the feedstock, temperature distribution inside the mold cavity, and residual stress distribution. Computer simulation techniques play a vital role in the design of powder injection molding molds.

3. Debinding Process:

Debinding involves the removal of organic materials from the molded body through heating and other physical methods while producing minimal sintering. Compared to other processes like formulation, molding, sintering, and post-processing of ceramic components, debinding is the most challenging and critical factor in injection molding. Incorrect debinding methods and parameters can result in inconsistent shrinkage, leading to deformation, cracking, stress, and inclusions. Debinding is also crucial for subsequent sintering, as cracks and deformations generated during debinding cannot be compensated for during sintering. The choice of binder determines the debinding method. Currently, debinding processes include traditional thermal debinding, solvent debinding, catalytic debinding developed in recent years, and water-based extraction debinding.

4. Sintering:

After debinding, ceramic green bodies are densified through high-temperature sintering to achieve the desired appearance, dimensional accuracy, and microstructure of the finished ceramic components. Due to the presence of pores in the ceramic injection molding green bodies resulting from debinding, significant shrinkage occurs during sintering, typically around 13%-15%. Therefore, controlling dimensional accuracy during sintering is a key research focus of CIM technology. Additionally, sintering equipment plays a crucial role in sintering technology.

Applications of CIM Ceramic Injection Molding

Currently, injection molding technology has been applied in the production of various high-performance ceramic products. Examples include ceramic medical devices for the biomedical field, ceramic brackets and ceramic posts for orthodontic and restorative dentistry, zirconia ceramic ferrules and ceramic sleeves for optical communication, alumina ceramic insulation components for the semiconductor and electronics industry, such as integrated circuit high packaging shells and small ceramic vacuum switch shells, as well as ceramic knives, ceramic watchbands, and ceramic watch cases used in modern life and the watch industry.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat