What is Tungsten?

Tungsten also called Tungsten Steel. The element tungsten, W, is a transition metal with an atomic number of 74, it is an extremely dense and heat-resistant chemical element. Melting at 3422 ℃, tungsten is one of the highest melting points among pure metals and the second rank among all chemical elements. Tungsten has the density of 19.25 g/cm³, which is higher than uranium, lead, and most other post-uranium elements.

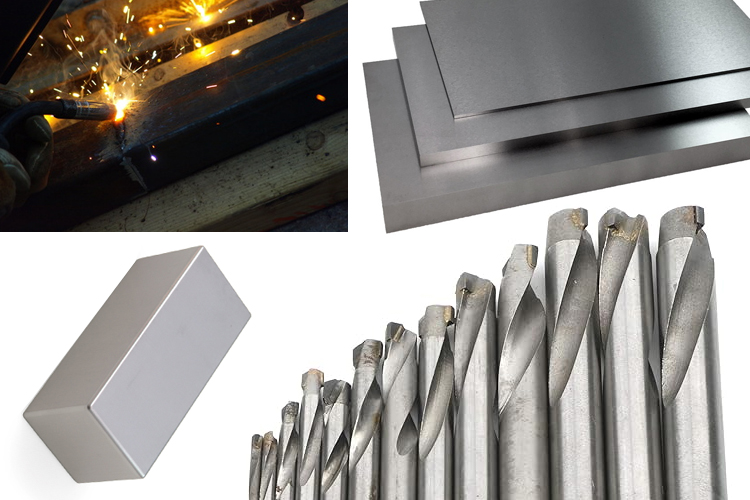

Putting tungsten into other alloy can increases the alloy's hardness and heat resistance, and make equipment made from tungsten steel wear-resistant and able to maintain high performance at high temperatures. Tungsten steel, as a tool steel, is widely used in industry, commonly adopted for processing other metals in tools and machinery, such as molds and cutting tools.

Tungsten is also a primary alloying element in some hot work tool steels, which are used to produce tools that can stand high temperatures. These hot work tool steels must also withstand the stresses caused by rapid temperature changes (thermal shock). Hot work tungsten steel typically contains high chromium and sometimes vanadium. It is used in extrusion and forging dies and other equipment for processing metals that are heated.

Types of tungsten steel

High-speed steel (HSS):

HSS is a type of tungsten steel that can maintain its hardness and toughness at high temperatures. This ability makes it perfect for cutting tools, such as drills, milling cutters, and taps.

Tool steel:

Tool steel is a kind of tungsten steel that has good performance of hardness and wear resistance. This feature make it suitable for for tools that are subjected to high levels of stress and wear, such as dies, punches, and cutting tools.

Hot work steel:

Hot work steel is a tungsten steel that is designed to withstand high temperatures and oxidation. This makes it ideal for tools and components that are used in hot environments, such as forging dies, furnace parts, and jet engine components.

Cold work steel:

Cold work steel is a type of tungsten steel that is designed to withstand high pressures and deformation. This makes it ideal for tools and components that are used in cold forming operations, such as dies, punches, and shears.

Stainless steel:

Stainless steel is a type of steel that contains chromium, which gives it resistance to corrosion. Tungsten is often added to stainless steel to improve its strength and wear resistance.

Hardness of Tungsten Steel

Tungsten steel can achieve a hardness of 89~95 HRA. With this features, products made from tungsten steel (commonly seen in tungsten steel watches) are characterized by their resistance to wear, hardness that doesn't easily anneal. Howevera, it is also brittle steel, not as tough as other alloy. The main components of tungsten steel (hard alloy) are tungsten carbide and cobalt, which has 99% of all the components, leave other metals 1%. This is why this alloy is referred to as tungsten steel.

Tungsten steel (hard alloy) possesses a range of excellent properties, including high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance. Its high hardness and wear resistance,in particular, remain relatively unchanged even at temperatures as high as 500°C, and it still maintains a high level of hardness at 1000°C.

Hard alloys are widely used as materials for tools such as turning tools, milling cutters, planers, drills, and boring tools. They are used for cutting materials like cast iron, non-ferrous metals, plastics, synthetic fibers, graphitglass, stone, and common steel. They can also be used for cutting difficult-to-machine materials like heat-resistant steel, stainless steel, high manganese steel, and tool steel. The cutting speed of new hard alloys can be hundreds of times faster than that of carbon steel.

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat