CNC machining is a manufacturing process that using computer-controlled machines to remove material from a workpiece to create a desired part or product. The machining time is the amount of time that takes for the CNC machine to complete the required operations on a workpiece,it is an important factor in CNC (Computer Numerical Control) machining.

CNC machining time is important for a number of reasons as below:

First, it is a major factor in the cost of CNC machining.

The longer it takes to machine a part, the more expensive it will be.

Second, machining time can affect the quality of the finished part. If the machining time is too short, the cutting tool may not have enough time to remove all of the material necessary to achieve the desired finish quality.

Third, machining time can also affect the efficiency of the manufacturing process. If the machining time is too long, it can lead to bottlenecks and delays in production.

As it is so important, then what factors can affect the CNC machining time?

Here are some factors that determine the CNC machining time:

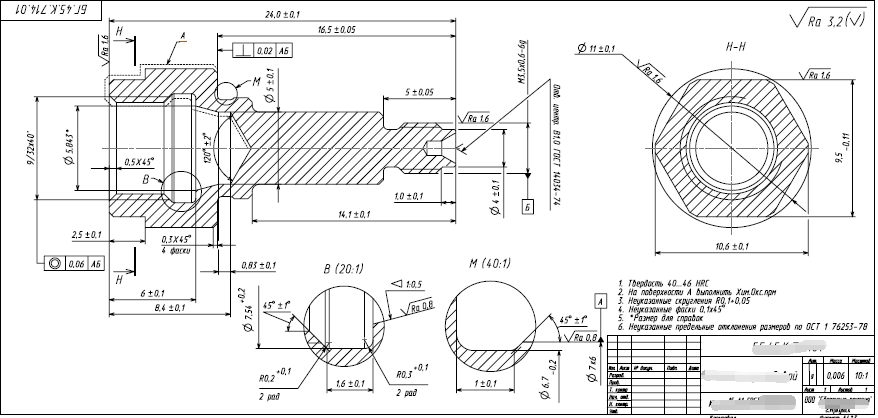

(1) Geometric complexity: The geometry and complexity of the part are the main factors affecting the machining time. More complex geometries often require more cutting operations and paths, resulting in longer machining times.

(2) Processing process: Different processing operations, such as turning, milling, drilling, etc., will affect the processing time. The machining speed and depth of cut of each operation affect the total time.

(3) Cutting data: Cutting parameters such as cutting speed, feed speed and cutting depth will affect the processing time. Proper parameter settings can improve efficiency, but if not set properly, part quality may be affected.

(4) Material: The hardness, toughness and other characteristics of the processed material will affect the cutting speed and tool life, thereby affecting the processing time.

(5) Tool selection: The type, size and material of the tool will also affect the processing time. Different tools have different cutting capacity and life.

(6) Tool replacement and setting time: It may be necessary to change the tool or make adjustments several times during the machining process. The time for tool change and setup increases the total machining time.

(7) Machine tool performance: The performance and accuracy of the machine tool will affect the processing speed and quality. More advanced machine tools usually have higher machining speed and precision.

(8) Program writing time: It also takes a certain amount of time to write CNC machining programs. Complex geometries and machining paths can take longer to write.

(9) Post-processing and inspection: After processing, post-processing and parts inspection are also required. These steps also increase the total time.

Also, we have some method to estimate the rough CNC machining time:

1) Estimation based on historical data of similar parts.

2) Use the machining manual or software to estimate the machining time.

3) Consider the average time of each process and add up the time of each process.

4) Consider factors such as cutting data, tools and materials, and use the machining time formula to estimate. For more accurate estimation, professional CNC machining software can be used, and the geometric data, cutting data and tool information of the part can be entered, and the software will generate a more accurate machining time estimate. As; Speed-plus "AI intelligent automatic quotation system".

Contact: Amanda

Phone: +86 180 2439 5054

Tel: 18666857627

Email: amanda@1fcnc.com

Add: No. 1395, Chang'An Section, Tai'An Road, Chang'An Town, Dongguan City, Guandong Province, China

We chat